| Availability: | |

|---|---|

| Quantity: | |

KEYUAN

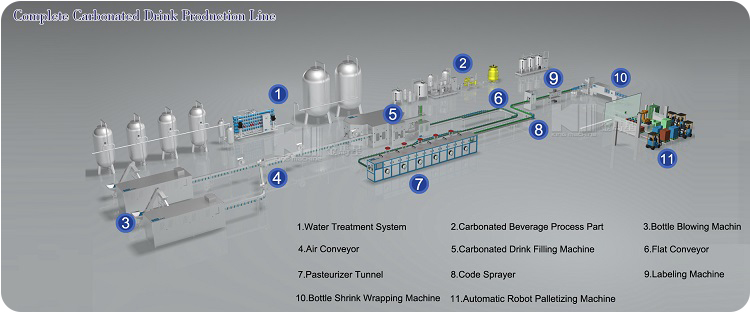

Our state-of-the-art High Speed Carbonated Drink Filling Machine is designed to meet the demanding requirements of the beverage industry. This advanced Carbonated Drink Filling Machine offers superior quality, efficiency, and reliability for your PET bottle filling needs.

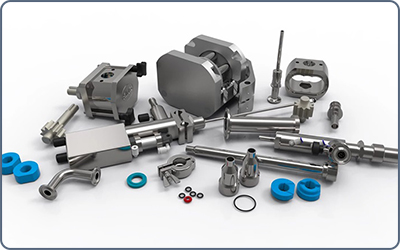

Direct air conveyor connection for smooth bottle transport

304/316 stainless steel rinse heads with efficient spray injection design

Water-saving technology for reduced consumption and enhanced cleaning

Stainless steel grippers with plastic padding to minimize bottle damage

Durable 304/316 stainless steel washing pump

High-precision 304/316 stainless steel filling nozzles

Fine-tuned adjustable filling volume for consistent liquid levels

Fully stainless steel contact parts and liquid tank with polished finish

No dead corners for easy cleaning and maintenance

Efficient 304/316 stainless steel filling pump

Advanced spray nozzle design for thorough rinsing with minimal water usage

Innovative place-and-cap system with electromagnetic capping heads

Burden discharge function to reduce bottle damage during capping

Full 304/316 stainless steel construction for durability

Intelligent "No bottle, no capping" feature

Automatic stop function when bottles are lacking

Exceptional capping reliability with a defective rate of ≤0.2%

Our Carbonated Drink Filling Machine is backed by a comprehensive Quality Assurance System, leveraging our technical expertise and production capacity. We firmly believe that every step in the production process contributes to overall quality control, ensuring the highest standards for your bottling needs.

Superior build quality with 304/316 stainless steel componentsEfficient design for optimal performance and reduced resource consumptionEasy to clean and maintain, ensuring hygienic operationHigh-speed filling capabilities for increased productivityPrecision filling and capping for consistent product qualityDesigned to handle a wide range of carbonated beverages

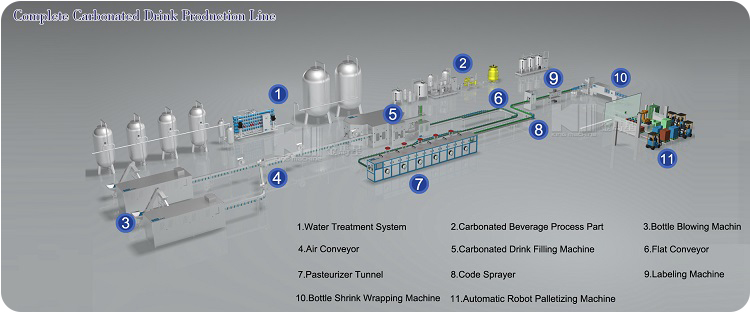

Our state-of-the-art High Speed Carbonated Drink Filling Machine is designed to meet the demanding requirements of the beverage industry. This advanced Carbonated Drink Filling Machine offers superior quality, efficiency, and reliability for your PET bottle filling needs.

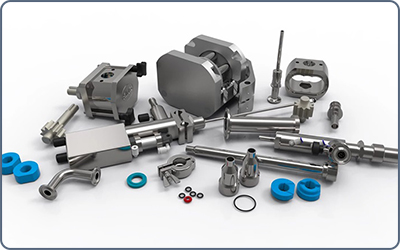

Direct air conveyor connection for smooth bottle transport

304/316 stainless steel rinse heads with efficient spray injection design

Water-saving technology for reduced consumption and enhanced cleaning

Stainless steel grippers with plastic padding to minimize bottle damage

Durable 304/316 stainless steel washing pump

High-precision 304/316 stainless steel filling nozzles

Fine-tuned adjustable filling volume for consistent liquid levels

Fully stainless steel contact parts and liquid tank with polished finish

No dead corners for easy cleaning and maintenance

Efficient 304/316 stainless steel filling pump

Advanced spray nozzle design for thorough rinsing with minimal water usage

Innovative place-and-cap system with electromagnetic capping heads

Burden discharge function to reduce bottle damage during capping

Full 304/316 stainless steel construction for durability

Intelligent "No bottle, no capping" feature

Automatic stop function when bottles are lacking

Exceptional capping reliability with a defective rate of ≤0.2%

Our Carbonated Drink Filling Machine is backed by a comprehensive Quality Assurance System, leveraging our technical expertise and production capacity. We firmly believe that every step in the production process contributes to overall quality control, ensuring the highest standards for your bottling needs.

Superior build quality with 304/316 stainless steel componentsEfficient design for optimal performance and reduced resource consumptionEasy to clean and maintain, ensuring hygienic operationHigh-speed filling capabilities for increased productivityPrecision filling and capping for consistent product qualityDesigned to handle a wide range of carbonated beverages

Normal | DCGF 14-12-4 | DCGF 18-18-6 | DCGF 24-24-8 | DCGF 32-32-10 | DCGF 40-40-12 | DCGF 50-50-15 |

Capacity bottle/500ml/hour | 2000-3000 | 3000-5000 | 5000-7000 | 7000-10000 | 10000-15000 | 16000-20000 |

Floor Area | 400m2 | 600m2 | 1000m2 | 2000m2 | 2500m2 | 2500m2 |

Total Power | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA | 600KVA |

Workers | 8 | 6 | 6 | 6 | 6 | 6 |

Normal | DCGF 14-12-4 | DCGF 18-18-6 | DCGF 24-24-8 | DCGF 32-32-10 | DCGF 40-40-12 | DCGF 50-50-15 |

Capacity bottle/500ml/hour | 2000-3000 | 3000-5000 | 5000-7000 | 7000-10000 | 10000-15000 | 16000-20000 |

Floor Area | 400m2 | 600m2 | 1000m2 | 2000m2 | 2500m2 | 2500m2 |

Total Power | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA | 600KVA |

Workers | 8 | 6 | 6 | 6 | 6 | 6 |